Reeds: The Internal Geometry of Hard D vs Back D

Originally published in The Pipers' Review 2009

Thereís

a well-known penalty for an increasingly easy hard D: a weak back D. In

addition to the exterior adjustments of scrape and length trimming, thereís

an interior geometric factor that can be manipulated and often with very

little change to the blades. The key is the change of curvature at the

tip of the blades, a curve that in traditionally made reeds gradually increases

from the lips toward the staple.

Thereís

a well-known penalty for an increasingly easy hard D: a weak back D. In

addition to the exterior adjustments of scrape and length trimming, thereís

an interior geometric factor that can be manipulated and often with very

little change to the blades. The key is the change of curvature at the

tip of the blades, a curve that in traditionally made reeds gradually increases

from the lips toward the staple.

If the curvature remains almost as shallow as at the lips, too far along

the blade toward the staple, hard D becomes easier while back D becomes

more unstable. Since reeds often flatten especially in the tip end a bit

as they age, this is an important reasn that back Dís can weaken over time.

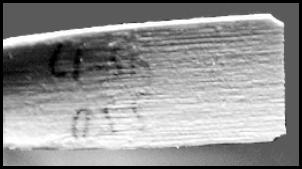

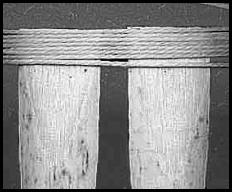

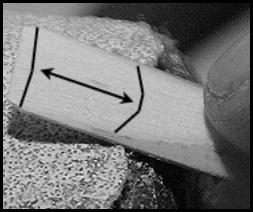

This reed had aged into a sinking back D, along with a very easy hard D,

and the photo of the inside of a blade shows why. The shadow shows that

the entire top 1/3 of the blade, at the right side of the photo, has the

same shallow curve as the lips.

The

traditional remedy is to trim the lips or move the bridle higher. But with

so much of the end of the blade having relaxed into the same very low curvature,

adjustment from the outside may not have revived it. So even though this

blade was already scraped thin, it was worth trying to create a greater

interior arch just below the lips by sanding the interior on a curved cylinder.

Only a tiny amount of cane needs to be removed, little enough that often

the blade is not weakened too much.

The

traditional remedy is to trim the lips or move the bridle higher. But with

so much of the end of the blade having relaxed into the same very low curvature,

adjustment from the outside may not have revived it. So even though this

blade was already scraped thin, it was worth trying to create a greater

interior arch just below the lips by sanding the interior on a curved cylinder.

Only a tiny amount of cane needs to be removed, little enough that often

the blade is not weakened too much.

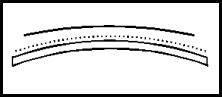

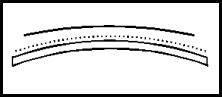

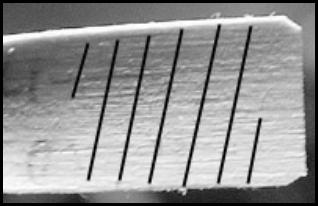

A

wide cylinder that is only slightly more curved than the lips is chosen,

medium to fine sandpaper placed on it indicated by the dotted line in the

diagram, and the upper end of the reed interior is sanded on it. Approach

the lips no closer than about 3/16Ē or 4-5 mm. The photograph shows the

region to be sanded. If the particular blade has more curvature around

the middle of the scrape, cut your sanding length in half or so, still

beginning near the lips, but reaching only a short distance toward the

staple. If a cylinder is used too far toward the tails, it begins to cut

into the edges of the reed and cause leaking.

A

wide cylinder that is only slightly more curved than the lips is chosen,

medium to fine sandpaper placed on it indicated by the dotted line in the

diagram, and the upper end of the reed interior is sanded on it. Approach

the lips no closer than about 3/16Ē or 4-5 mm. The photograph shows the

region to be sanded. If the particular blade has more curvature around

the middle of the scrape, cut your sanding length in half or so, still

beginning near the lips, but reaching only a short distance toward the

staple. If a cylinder is used too far toward the tails, it begins to cut

into the edges of the reed and cause leaking.

If the low interior curvature has also caused the octave to go flat,

you can use a 2nd or 3rd cylinder, increasingly narrow,

to sand increasingly curved zones closer and closer to the position of

the staple eye. This will open up more airspace inside the head, flattening

the 1st octave and sharpening the 2nd octave a bit.

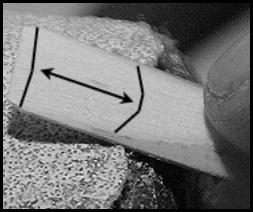

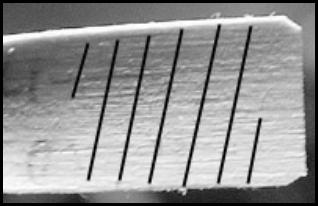

The

change in this blade was so little that itís difficult to photograph clearly,

so Iíve overlaid black lines to illustrate the area that was sanded. You

may be able to see in this view that the very tip of the reed at right

is a bit smoother than the area under the lines, and that there is just

a little more shadow visible under the upper edge (in the photo) of the

blade indicating that the blade has a small increase of curvature.

The

change in this blade was so little that itís difficult to photograph clearly,

so Iíve overlaid black lines to illustrate the area that was sanded. You

may be able to see in this view that the very tip of the reed at right

is a bit smoother than the area under the lines, and that there is just

a little more shadow visible under the upper edge (in the photo) of the

blade indicating that the blade has a small increase of curvature.

When this reed was reassembled, the back D was strong again, without

any trimming of the lips, and the hard D was not compromised.

Both blades need to be examined. Itís not unusual for one blade to be

more flattened than the other, and in that case only the flatter blade

may need treatment.

If instead back D is solid while hard D is very difficult to sound,

the upper interior is often too curved close to the lips.

If the edges and corners are reasonably thick, sanding the very tip

on a slightly wider cylinder may ease the hard D a little. Otherwise the

blades can be wet, and the upper ¼Ē of the tip firmly bound onto

a wider cylinder, and allowed to dry for several days.

David Daye

Cuyahoga Falls, OH

Thereís

a well-known penalty for an increasingly easy hard D: a weak back D. In

addition to the exterior adjustments of scrape and length trimming, thereís

an interior geometric factor that can be manipulated and often with very

little change to the blades. The key is the change of curvature at the

tip of the blades, a curve that in traditionally made reeds gradually increases

from the lips toward the staple.

Thereís

a well-known penalty for an increasingly easy hard D: a weak back D. In

addition to the exterior adjustments of scrape and length trimming, thereís

an interior geometric factor that can be manipulated and often with very

little change to the blades. The key is the change of curvature at the

tip of the blades, a curve that in traditionally made reeds gradually increases

from the lips toward the staple. The

traditional remedy is to trim the lips or move the bridle higher. But with

so much of the end of the blade having relaxed into the same very low curvature,

adjustment from the outside may not have revived it. So even though this

blade was already scraped thin, it was worth trying to create a greater

interior arch just below the lips by sanding the interior on a curved cylinder.

Only a tiny amount of cane needs to be removed, little enough that often

the blade is not weakened too much.

The

traditional remedy is to trim the lips or move the bridle higher. But with

so much of the end of the blade having relaxed into the same very low curvature,

adjustment from the outside may not have revived it. So even though this

blade was already scraped thin, it was worth trying to create a greater

interior arch just below the lips by sanding the interior on a curved cylinder.

Only a tiny amount of cane needs to be removed, little enough that often

the blade is not weakened too much. A

wide cylinder that is only slightly more curved than the lips is chosen,

medium to fine sandpaper placed on it indicated by the dotted line in the

diagram, and the upper end of the reed interior is sanded on it. Approach

the lips no closer than about 3/16Ē or 4-5 mm. The photograph shows the

region to be sanded. If the particular blade has more curvature around

the middle of the scrape, cut your sanding length in half or so, still

beginning near the lips, but reaching only a short distance toward the

staple. If a cylinder is used too far toward the tails, it begins to cut

into the edges of the reed and cause leaking.

A

wide cylinder that is only slightly more curved than the lips is chosen,

medium to fine sandpaper placed on it indicated by the dotted line in the

diagram, and the upper end of the reed interior is sanded on it. Approach

the lips no closer than about 3/16Ē or 4-5 mm. The photograph shows the

region to be sanded. If the particular blade has more curvature around

the middle of the scrape, cut your sanding length in half or so, still

beginning near the lips, but reaching only a short distance toward the

staple. If a cylinder is used too far toward the tails, it begins to cut

into the edges of the reed and cause leaking. The

change in this blade was so little that itís difficult to photograph clearly,

so Iíve overlaid black lines to illustrate the area that was sanded. You

may be able to see in this view that the very tip of the reed at right

is a bit smoother than the area under the lines, and that there is just

a little more shadow visible under the upper edge (in the photo) of the

blade indicating that the blade has a small increase of curvature.

The

change in this blade was so little that itís difficult to photograph clearly,

so Iíve overlaid black lines to illustrate the area that was sanded. You

may be able to see in this view that the very tip of the reed at right

is a bit smoother than the area under the lines, and that there is just

a little more shadow visible under the upper edge (in the photo) of the

blade indicating that the blade has a small increase of curvature.